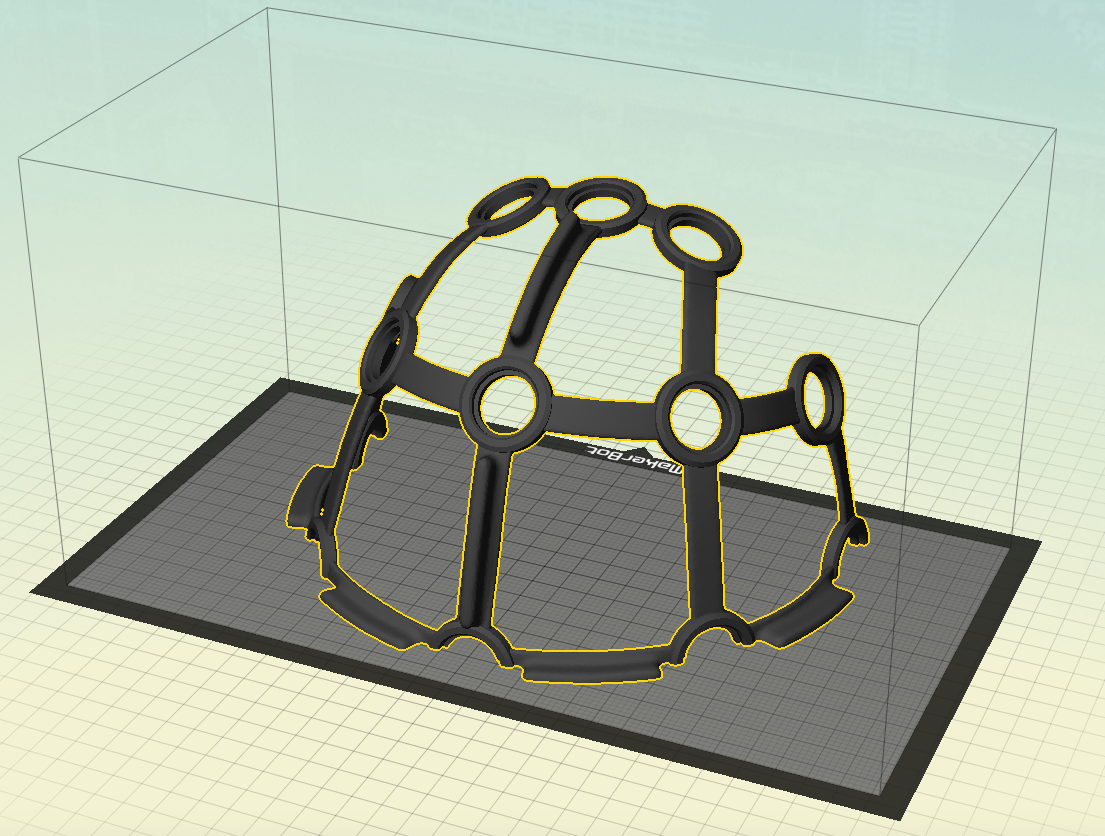

Ultracortex Mark 2

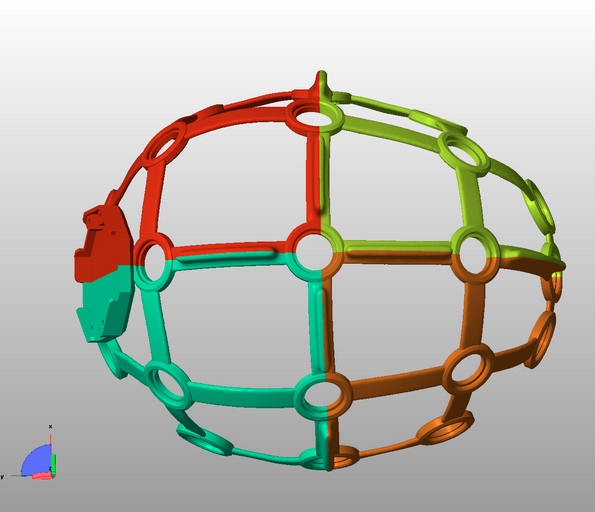

Print Settings (verified)

- Printer used: Makerbot Rep 2

- Material: PLA

For M2-Frame Components

- Resolution: Low (Faster)

- Raft: Yes

- Supports: Yes (even though this uses A LOT of extra material)

- Infill: 100% (we want it sturdy)

- Number of shells: 3

- Layer Height: 0.3mm

- Temperature: 235 C

- Speed while Extruding: 45 mm/s (you may be able to increase this depending on how well tuned your 3D printer is)

- Speed while traveling: 150 mm/s

For M2-Electrode-Mount Components

- Resolution: Low (Faster)

- Raft: No

- Supports: No

- Infill: 100% (we want it sturdy)

- Number of shells: 3

- Layer Height: 0.3mm

- Temperature: 235 C

- Speed while Extruding: 45 mm/s (you may be able to increase this depending on how well tuned your 3D printer is)

- Speed while traveling: 150 mm/s

Spring Options

We are in the process of testing different springs to be nested

Spring 1 (tested)

McMaster-Carr > 1 9657K279 Steel Compression Spring, Zinc-Plated Music Wire, .500" L, .600" OD, .045" Wire, Packs of 12

Summary: The ~23 lb/in is too strong!

Spring 2 (tested)

centuryspring.com: Custom spring order of Part # B6-8

Summary: custom order... ~1 lb/in is too weak...

Spring 3 & 4 (untested, but potentially better)

Our working version of the headset uses Springs 1 & 2, but I would recommend trying the following instead:

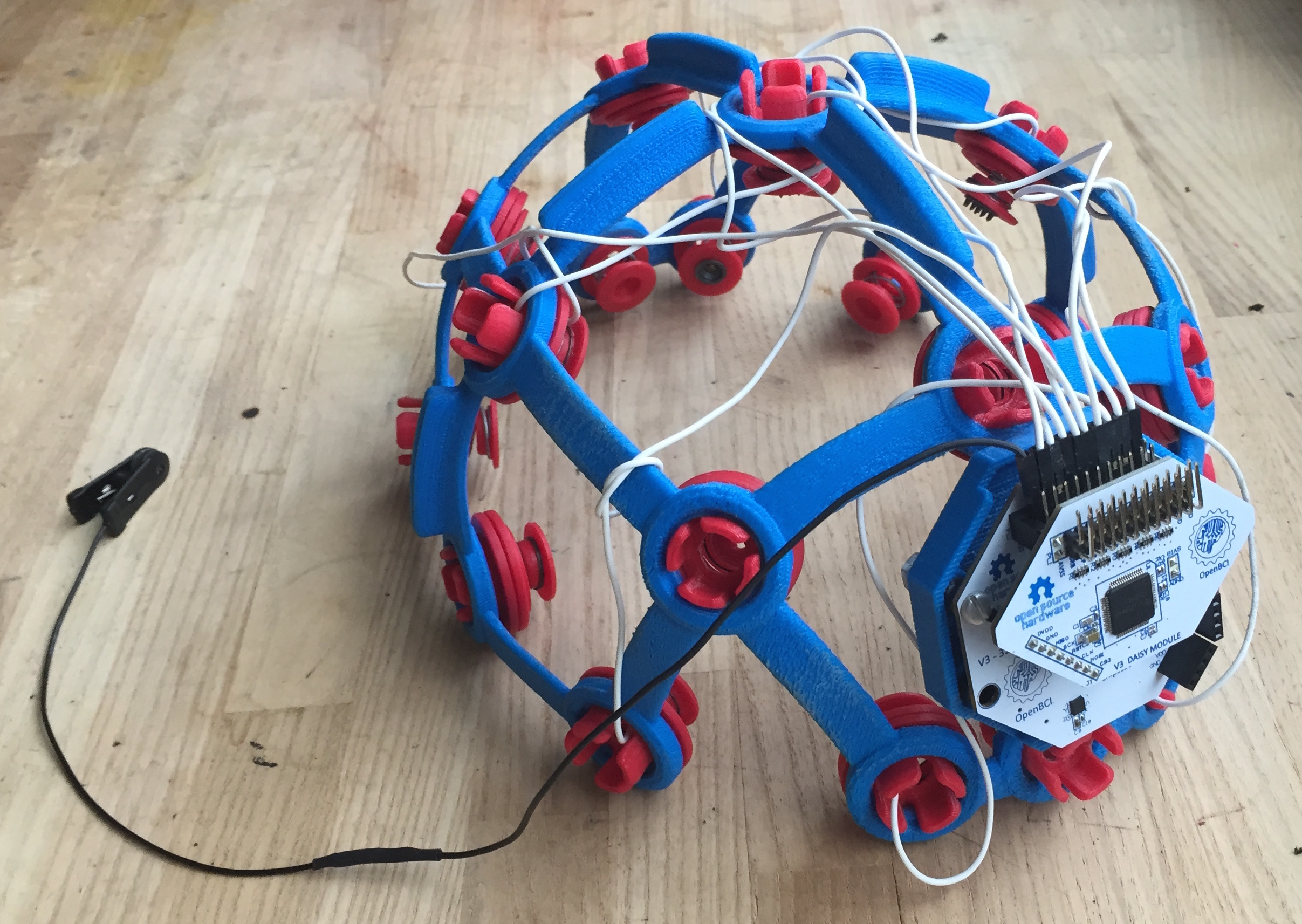

Electrodes

Dry (spikey) electrodes to be installed in Ultracortex nodes with hair:

Dry (non-spikey) electrodes to be installed in Ultracortex nodes without hair (forehead, for instance):

Ear Clip electrode (for reference)

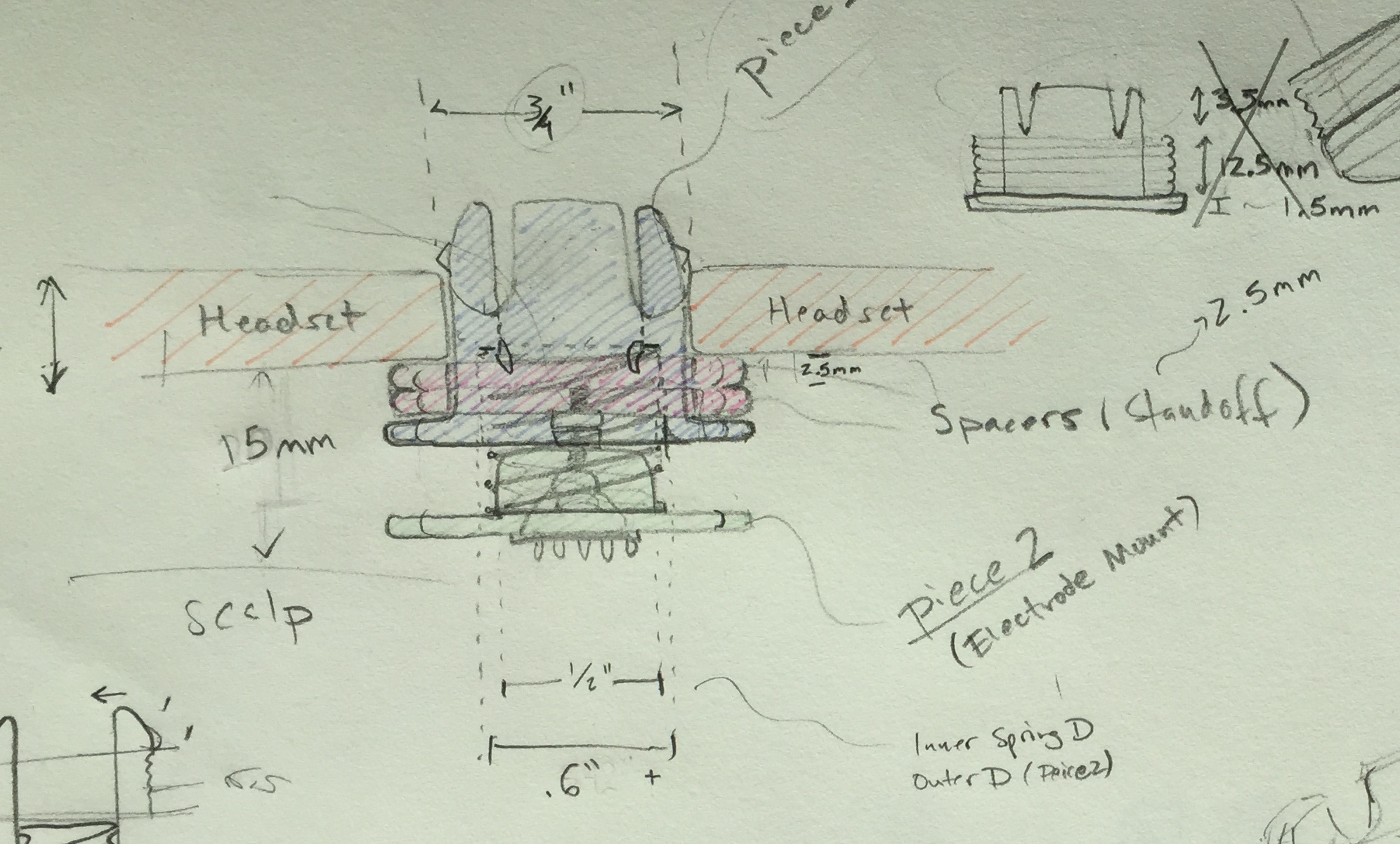

Nuts & Bolts for Connecting Electrodes

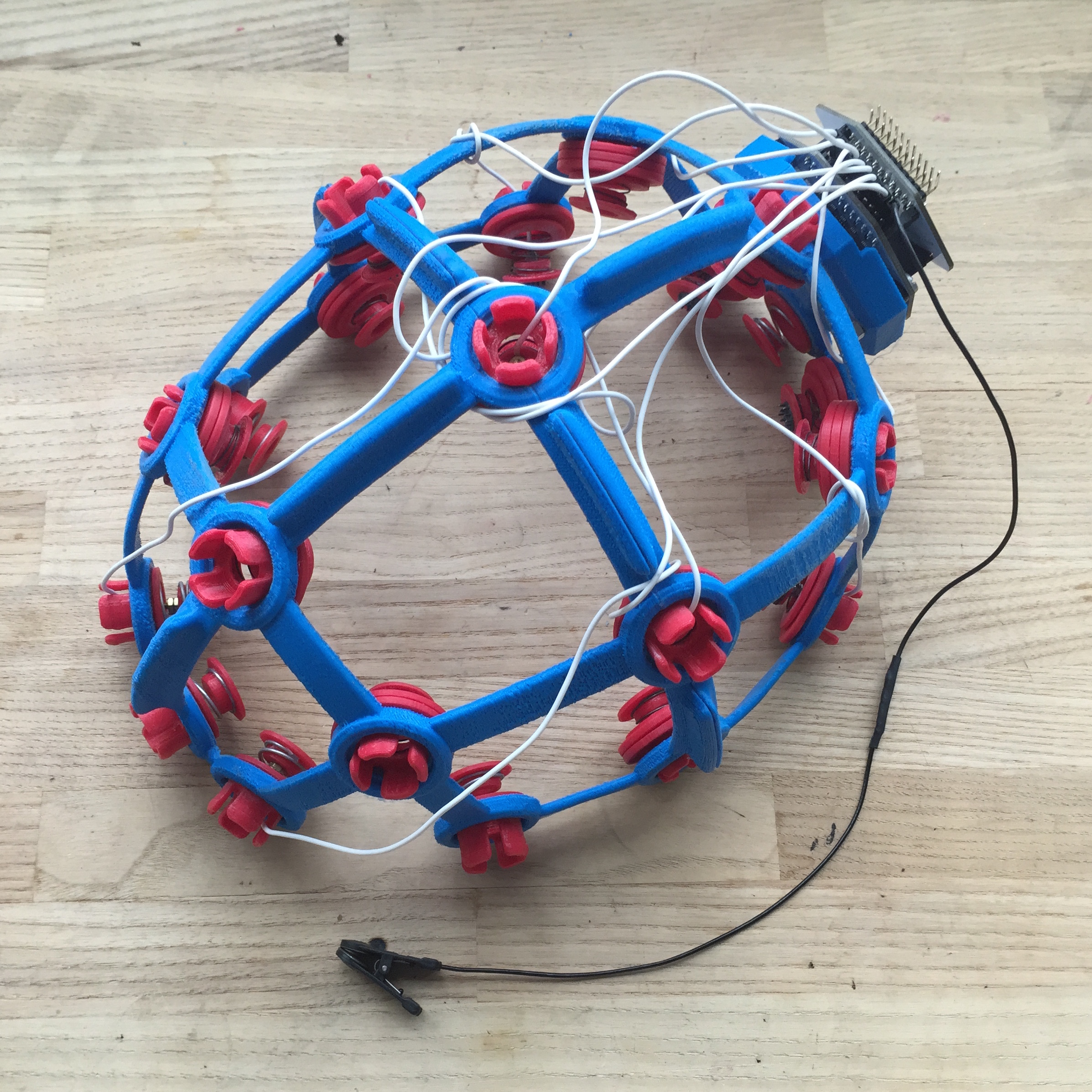

We use small stainless steel screws and hex nuts to fasten the FRI electrodes (listed above) to the 3D-printed electrode mount components & wiring that connects the electrodes back to the OpenBCI board. We used stripped Gold Cup Electrodes electrodes as the cabling, by removing the gold cup with a wire cutter and looping the exposed wire around the screw between the two tightened hex nuts (as seen in the picture below).

- Stainless Steel Pan Head Phillips Machine Screw, 2-56 Thread, 3/8" Length ($5.70 per pack of 50)

- Stainless Steel Hex Nut, 2-56 Thread Size, 3/16" Wide, 1/16" High

Other Helpful Information

- The following equipment/accessories were either necessary or very helpful in the assembly of this headset.

- super glue

- sandpaper

- coarse flat & circular files

- some sort of flexible wiring (terminating in a female header) to connect the electrodes back to the OpenBCI board. We used stripped Gold Cup Electrodes electrodes & stripped touch-proof connector cabling.

- an exacto/razor blade

- wirecutters

- needle-nose pliers

- The "M2_Electrode Mount A_01" part has a small lip on the inside (where the spring fits into) that must be manually removed with an exacto/razor blade.

- Most of the tolerances between pieces are too tight, so assembly requires substantial filing and sanding.

- The "M2_Electrode Spacer_01" part is used to adjust for different head shapes and sizes

- With this versoin (M2) we unfortunately only have one frame size, so this headset will not fit most heads, even with the spacers and springs.

- Before printing, make sure to re-orient the frame STLs so the flat sides of the model are on the platform.

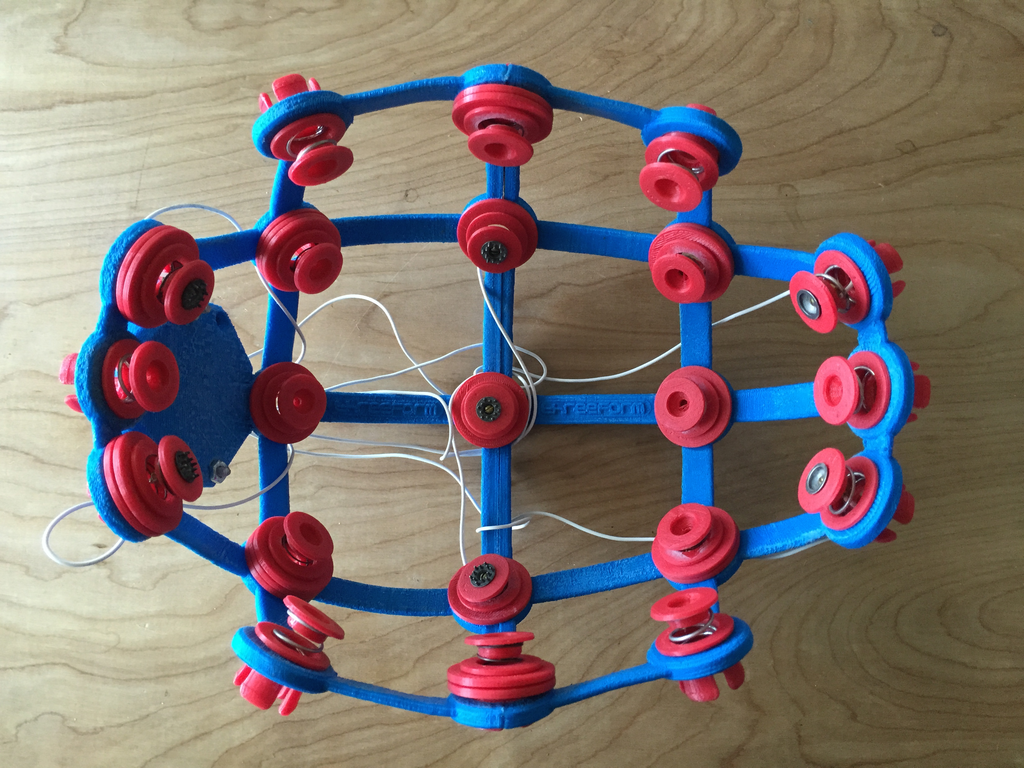

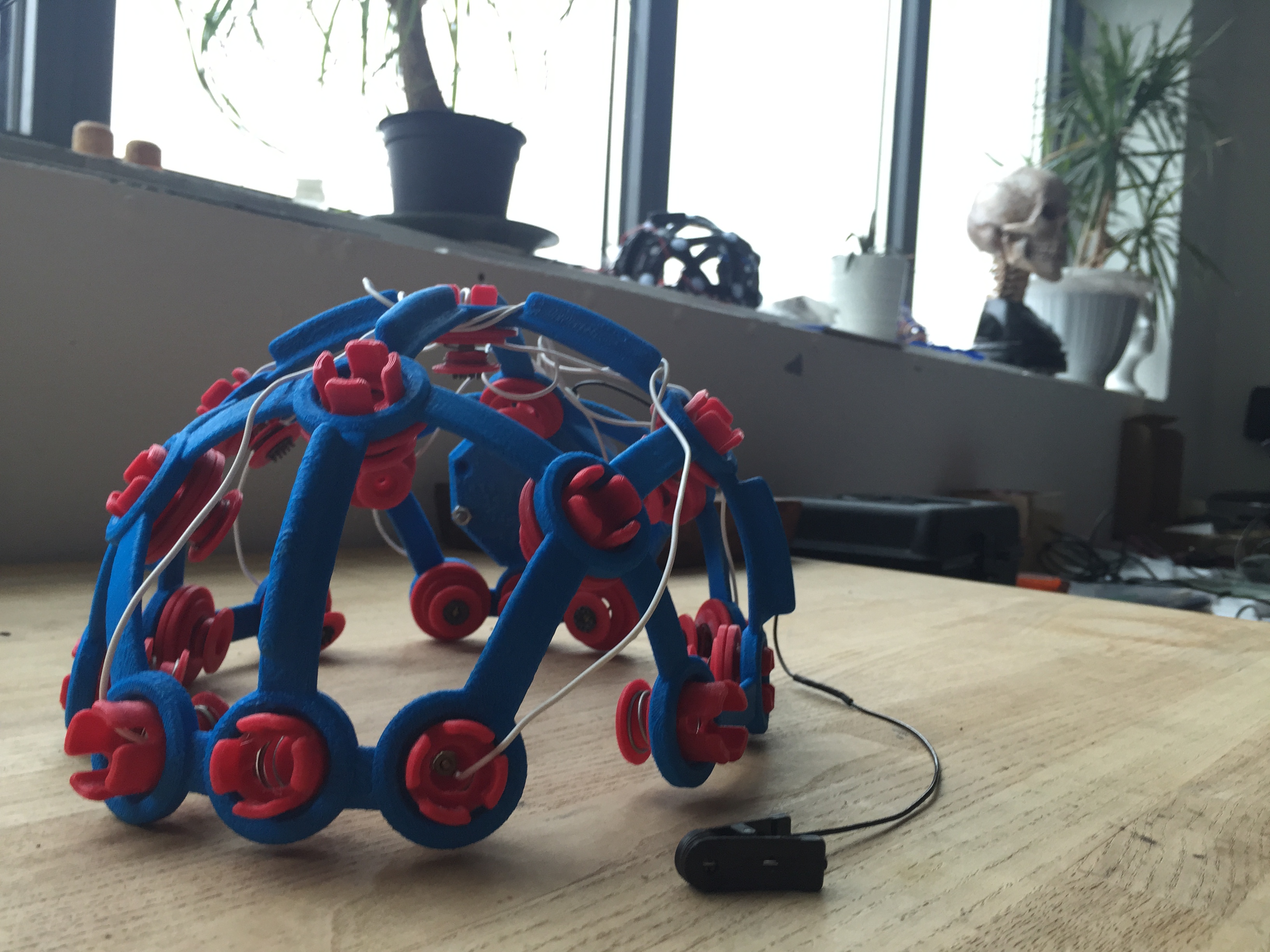

Photos of Ultracortex M2